Omega watches are some of the best in the world. They’re made by one of the oldest watch companies in Switzerland, and they’ve been around for over 150 years. When one thinks about luxury watches, Omega watches are often one of the three top brands that come to mind.

Where exactly do these wonderful timepieces come from? Let’s start at the beginning…

A Brief History of Omega’s Manufacture

Before adopting the name, Omega, the company ran under the name of its founder Louis Brandt.

1848 – Founded in the Chaux de Fonds

A portrait of Louis Brandt (photo: Omega)

You may have heard of Louis Brandt, the watchmaker who founded Omega in 1848. But did you know that he was also responsible for creating an observatory in his hometown of Chaux-de-Fonds? The Neuchatel Observatory was one of the first official chronometer testing institutes in Switzerland and remains one of only two such institutions today.

The first Omega headquarters was located at Rue du Petit-Chêne 6 in Chaux-de-Fonds, Neuchâtel Switzerland.

Louis Brandt died in 1879 leaving the popular company to his two sons, Louis-Paul and César. His sons were able to continue the business and help it thrive and grow.

1882 – Omega moves to Bienne/Biel

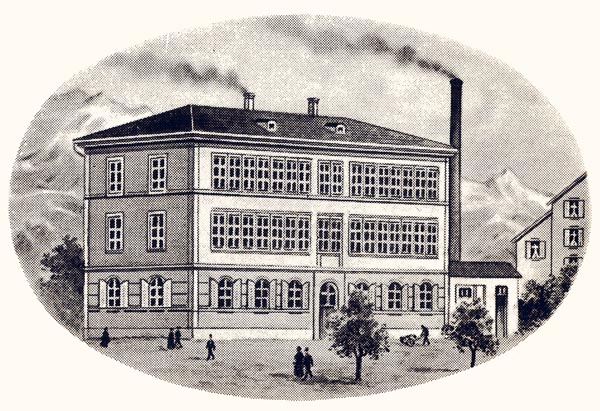

Omega’s first home in Biel/Bienne (photo: Omega)

In 1882, the company moved its headquarters to Biel and has been there ever since.

The brothers continued to grow the company and their research. In 1894, they created a movement that changed the standards of watchmaking. This extremely accurate movement called 19-ligne calibre, introduced the ability to wind and set the watch with the stem and crown we know today.

The original Omega calibre, the company’s namesake (photo: Omega)

Around this time the brothers decided to rename the company, using the last letter of the Greek alphabet to signify their great accomplishment. By 1903, the company was officially known as the Omega Watch Co. and was the largest manufacturer of watches in Switzerland.

Villeret became the home of their manufacturing warehouse. After manufacturing, the parts are moved to their headquarters in Bienne for final assembly and testing. Inside the Villeret facility the cases, bracelet links, bezels, the various movements, crystals, and dials are all made from the parts they make themselves or import from other companies.

There are 300 expertly trained watchmakers that make this possible. Each of these specialists is responsible for a single part of the watch. This ensures that each part is made and assembled to absolute perfection.

2017 – Opened new factory in Bienne

Omega’s new headquarters (photo: Omega)

A new state-of-the-art factory was inaugurated in 2017. While components are still imported, made, and assembled at their factory at Villeret, the new site is designed to function as the location for watch assembly, bracelet production, and shipping.

<>

The Omega Factory in Bienne, Switzerland

Omega’s headquarters in Bienne, Switzerland (photo: Omega)

This 5-story building designed by Japanese architect Shigeru Ban is as stunning as the watches made inside it. The building represents their eco-friendly stance and it is built with a combination of Swiss spruce and glass. It’s an impressive and awe-inspiring mix of concrete, metal, and glass with the warmth of wood. Even with all the wooden details, it only amounts to what they claim is 2.6 hours of tree growth in Switzerland. Swiss Spruce is a highly renewable resource.

With over 63,000 square meters of space, it houses skilled watchmakers, robots, and marketers all under one roof. All the parts are sent here to be assembled in a dust-free and temperature-regulated environment. This is only on two of the floors.

The building is an effort to streamline the production process. The steps completed in this new building include T2 or watch assembly, T3 or bracelets, and T4 or shipping. They also completed all their quality control testing and logistics here with a winning combination of technology, robotic, and human expertise. Visitors can view the whole process through windows, including the METAs certification testing.

Storage

Omega’s new production facility (photo: Omega)

Wrapped in the center of the building is a three-story storage facility that can house 30,000 new watches and luxury boxes at a time. This storage facility is controlled and regulated by a small robot until shipping. Visitors can investigate this impressive storage facility through some strategically placed windows. It’s right out of a sci-fi movie as the two little robots zip around moving and removing boxes of finished watches.

The impressive storage center has a top-notch climate control system that maintains an oxygen level of 15.2% (20.9% is normal). This is what you’ll find at a higher altitude of around 3,000m (9,000ft). Why do this you might ask? It reduces the chances of fire. When you’re talking about 30,000 luxury watches all stored in the same place, a fire would be devastating. This impressive system has a downside. There are only two people that are trained and authorized to enter this facility at any time, and only for maintenance.

Stock

Inside Omega’s factory (photo: Omega)

Also inside the facility is a central stock system very similar to the storage center. Powered by robotic operations, the stock center can. Be accessed by absolutely any employee. Any part they need to acquire will be in their hands in two minutes or less. Their computer system can trace each and every part from the moment it comes to the facility to when it’s requested. Even after it’s requested the system continues to track the part to the time, place, and object it’s been fitted to. In order to accomplish this, each workstation has a tablet fitted to it that accesses the system where they can request parts, assembly charts, and track accomplishments.

Human Element

Watchmaking in Omega’s headquarters (photo: Omega)

None of the robotic elements were ever designed to replace human expertise. Omega wanted the technology to enhance and streamline the capabilities of the expert watchmakers. This includes their work areas. Their workbenches are designed to increase their comfort with adjustable heights and positions. The tablets mentioned above help keep their stations clean and uncluttered.

<>

Omega Watches: Where are they made?

It is clear that Omega has a long history of making watches, but it is also clear that they are not afraid to change with the times.

The current state of their factory and production in Bienne shows this perfectly; they have taken steps towards being more environmentally friendly while still maintaining the high quality we expect from them.

Ready for your very own Omega watch? Check out our vast selcection of Omega watches at SwissWatchExpo.com. Put a piece of the past and the future on your wrist.